Gold Plating Services

Gold plating is a high-precision electroplating process that deposits a thin layer of gold onto metal surfaces to enhance conductivity, corrosion resistance, and surface stability. Known for its exceptional electrical performance and resistance to oxidation, gold plating is essential in critical applications across electronics, aerospace, medical, and defense industries.

Key Benefits

- Superior Electrical Conductivity: Ideal for connectors, switches, and high-performance electronic components.

- Corrosion & Tarnish Resistance: Gold does not oxidize, ensuring long-term surface integrity.

- Low Contact Resistance: Enhances signal reliability in precision components.

- Biocompatibility: Safe for medical and dental devices.

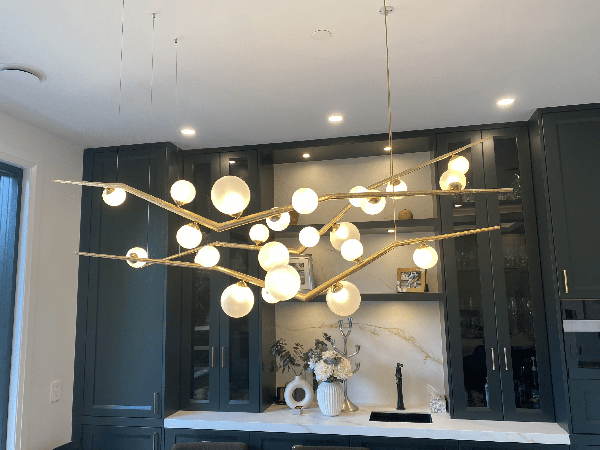

- Aesthetic Appeal: Provides a rich, bright finish suitable for decorative or branding purposes.

Capabilities

- Deposit Thickness: From 5 microinches to over 100 microinches (0.1-2.5 µm), based on functional or decorative needs.

- Finish Types: Hard gold, matte or bright finish available based on material surface condition.

- Base Materials: Suitable for copper, brass, stainless steel, and aluminum.

- Applications: Electronic contacts, aerospace components, medical instruments, RF connectors, and luxury hardware.

Compliant Specifications

Our gold plating processes meet industry standards such as:

- MIL-G-45204: Gold plating; Electrodeposited

- ASTM B488: Electrodeposited coating of gold for engineering uses

- AMS 2422: Gold plating

Gold plating ensures performance, reliability, and durability where it matters most—whether in mission-critical electronics or high-end decorative finishes.